RFID handheld terminal intelligent inspection system program

2017-12-29 17:49:43

Petrochemical, metallurgy, papermaking, medicine and other industrial enterprises need continuous production, process raw materials or production equipment, small changes that may cause the device, product, the production of a significant impact on the stringent requirements of the production process makes daily inspection Work is very important.

First, the inspection work in the existing problems

Many of the current process of industrial production inspection is not intelligent, inspection quality is not high: the current fake inspection, not according to the provisions of the inspection, leading to the production can not be found abnormal, to the production management caused a lot of trouble.

Inspection staff work site

Second, intelligent inspection program overview

Rui Feng Ed Technology for the existence of inspection problems, specifically developed RFID handheld terminal intelligent inspection program. The program regulates the inspection process of the inspector. The inspector prepares the operation process to the RFID handheld terminal in advance, scanning the RFID tag or one-dimensional two-dimensional code, registering the device information, taking live photos, real-time Upload information to the system background, and automatically record the results of each step, time, coordinates, order; at the same time inspectors can also view the history or trend, view the current job-related drawings and attachments, real-time access to the system background reminders The

Third, intelligent inspection program introduced

The four parts of the server, client, inspection point and handheld terminal are a real-time inspection and management system composed of GPS terminal and system management platform using GPRS network. The system through GPS satellite positioning technology, GIS geographic information technology, RFID radio frequency technology, GPRS / 3G / 4G network communication technology, WIFI data transmission technology inspection and recording, to achieve the purpose of intelligent inspection.

In the inspection process, through GPS technology, GIS technology to locate the inspector position, and through GPRS signal real-time upload data. When the inspector is within the scope of the patrol point, the PDA mobile terminal will automatically record the time, place and condition of the inspector in the inspection work, which will make the inspection work more scientific, standardized and greatly improved Work efficiency.

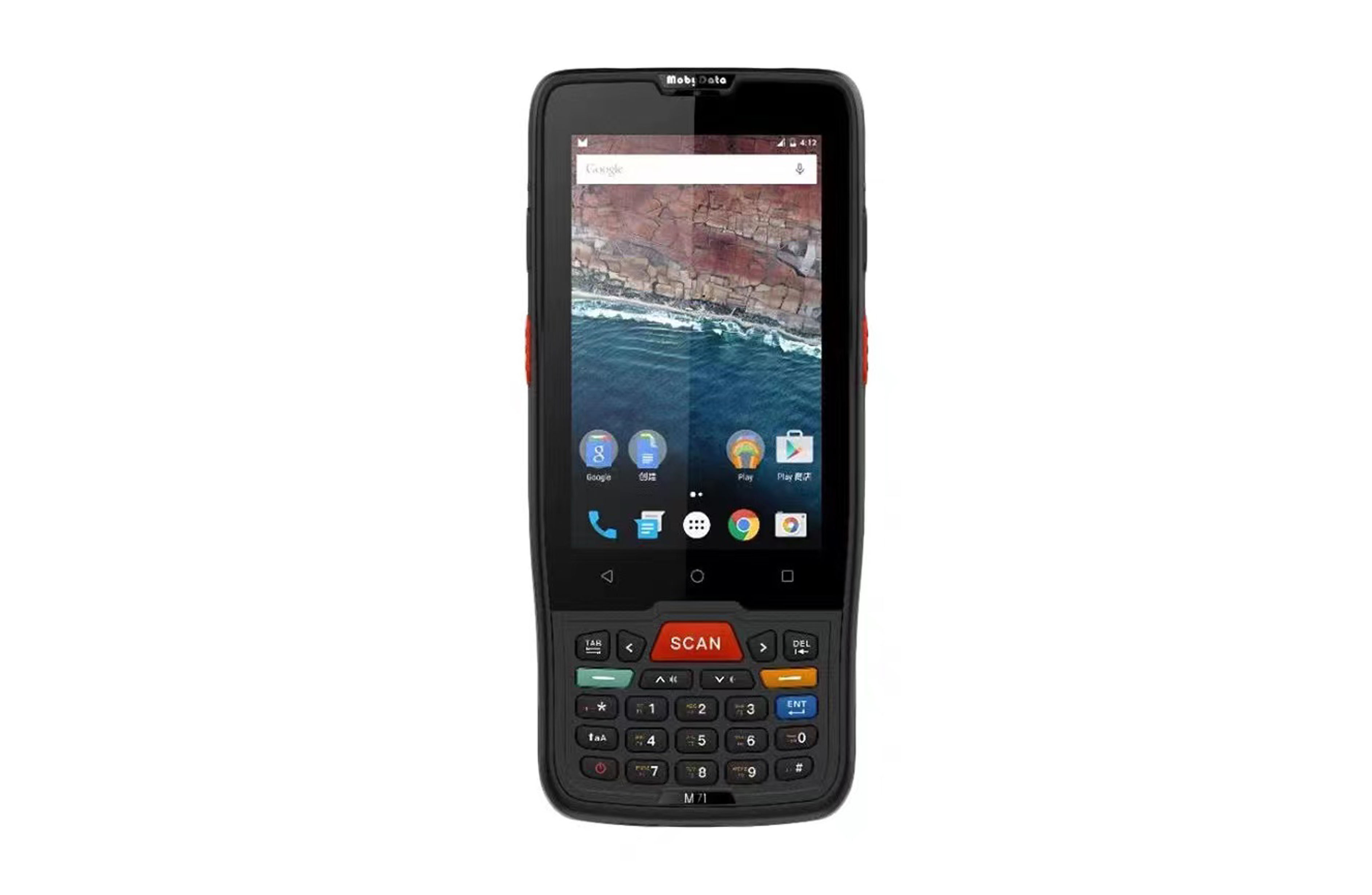

Handheld mobile terminal, carried by the inspectors, for reading and reporting data. During the inspection process, if you find any unusual problems, you can note through the text, the scene to take pictures, etc., the data back to the management center to facilitate the contingency plans.

Fourth, intelligent inspection program benefits

1, timely detection of problems, solve problems, and upload to the background, to provide decision support

2, standard staff inspection operation process, inspection quality can also be assessed, assessment

3, to improve management efficiency, at any time to check the inspection equipment situation

First, the inspection work in the existing problems

Many of the current process of industrial production inspection is not intelligent, inspection quality is not high: the current fake inspection, not according to the provisions of the inspection, leading to the production can not be found abnormal, to the production management caused a lot of trouble.

Inspection staff work site

Second, intelligent inspection program overview

Rui Feng Ed Technology for the existence of inspection problems, specifically developed RFID handheld terminal intelligent inspection program. The program regulates the inspection process of the inspector. The inspector prepares the operation process to the RFID handheld terminal in advance, scanning the RFID tag or one-dimensional two-dimensional code, registering the device information, taking live photos, real-time Upload information to the system background, and automatically record the results of each step, time, coordinates, order; at the same time inspectors can also view the history or trend, view the current job-related drawings and attachments, real-time access to the system background reminders The

Third, intelligent inspection program introduced

The four parts of the server, client, inspection point and handheld terminal are a real-time inspection and management system composed of GPS terminal and system management platform using GPRS network. The system through GPS satellite positioning technology, GIS geographic information technology, RFID radio frequency technology, GPRS / 3G / 4G network communication technology, WIFI data transmission technology inspection and recording, to achieve the purpose of intelligent inspection.

In the inspection process, through GPS technology, GIS technology to locate the inspector position, and through GPRS signal real-time upload data. When the inspector is within the scope of the patrol point, the PDA mobile terminal will automatically record the time, place and condition of the inspector in the inspection work, which will make the inspection work more scientific, standardized and greatly improved Work efficiency.

Handheld mobile terminal, carried by the inspectors, for reading and reporting data. During the inspection process, if you find any unusual problems, you can note through the text, the scene to take pictures, etc., the data back to the management center to facilitate the contingency plans.

Fourth, intelligent inspection program benefits

1, timely detection of problems, solve problems, and upload to the background, to provide decision support

2, standard staff inspection operation process, inspection quality can also be assessed, assessment

3, to improve management efficiency, at any time to check the inspection equipment situation